A quick overview of the topics covered in this article.

Subscribe to the UKPACK newsletter to receive regular updates on the company, products, services, upcoming exhibitions and more.

In 1951, J. Paul Hogan and Robert Banks of Phillips Petroleum showed that propylene could be polymerized. Then, in March 1954, Giulio Natta and Karl Rehn made a groundbreaking discovery when they found that it was possible to produce isotactic polypropylene through stereoselective polymerization.

As a result of this discovery, the Italian company Montecatini began large-scale commercial production of isotactic polypropylene in 1957. Natta was the first to synthesize syndiotactic polypropylene.

What is PP (Polypropylene) Plastic?

PP (Polypropylene) is a type of plastic that belongs to the polyolefin family. It is a thermoplastic polymer that is resistant to many chemicals and has a high melting point, making it a popular choice for a wide range of applications.

In addition, PP is known for its strength and durability, as well as its flexibility and versatility. It is often used to make a variety of products, including packaging materials for cosmetics, textiles, automotive parts, medical devices, etc.

What’s more, it is also resistant to moisture and is able to maintain its structural integrity even when exposed to high temperatures.

What are The Characteristics of PP?

Some key characteristics of PP plastic include:

High strength-to-weight ratio

Polypropylene has a high strength-to-weight ratio, making it suitable for use in lightweight, yet strong and sturdy products.

Chemical resistance

Polypropylene has excellent resistance to many acids, bases, and other chemicals, making it suitable for use in a variety of industrial and household applications.

Heat resistance

Polypropylene has a high melting point and can withstand high temperatures, making it suitable for use in a range of applications, including food packaging and automotive parts.

Low water absorption

Polypropylene has a low water absorption rate, meaning it is not easily affected by moisture. This makes it suitable for use in outdoor and marine applications.

Versatility

Polypropylene can be molded into a wide range of shapes and sizes, making it suitable for use in a variety of applications, including packaging, automotive parts, and textiles.

Non-toxic

Polypropylene is non-toxic and safe for use in food packaging and other applications where it may come into contact with humans or animals.

Low cost

Polypropylene is relatively inexpensive to produce, making it a cost-effective material for many applications.

Recyclable

Polypropylene can be easily recyclable and reprocessed, which makes it an environmentally friendly material.

What are The Applications of PP Plastic?

PP (Polypropylene) plastic is a versatile thermoplastic that can be used in a wide range of applications due to its strength, durability, and resistance to chemicals and high temperatures. Some of the most common applications of PP plastic include:

Packaging

PP is commonly used in food packaging such as yogurt cups, margarine tubs, and microwaveable trays. It can also be used for cosmetic packaging such as cosmetic bottles and jars for lotions, creams, serums, shampoos, etc.

Automotive

PP is widely used in the automotive industry, particularly in the production of car bumpers, battery cases, and interior and exterior trim.

Textiles

PP fibers are used in making carpets, upholstery, and ropes and webbings.

Household appliances

PP is commonly used in a wide range of household appliances such as washing machines, dishwashers, and vacuum cleaners.

Medical applications

PP is widely used in the medical industry, particularly in the production of surgical instruments and equipment, as well as in packaging for medical devices.

Industrial

PP is also widely used in the production of industrial parts and components, such as gears, bearings, and pump parts.

Agricultural

What’s more, PP is also used in the production of agricultural parts and components, such as crates, pallets, and tanks.

Consumer goods

In addition, PP is also used in the production of consumer goods such as toys, stationery, and containers for personal care products.

Construction

PP is used for pipes and fitting, sheets, profiles, and other similar items in construction.

These are just some examples of the many applications of PP plastic. Due to its properties and versatility, PP continues to be a popular choice in many other areas as well.

How is Polypropylene Produced?

Polypropylene is produced by the polymerization of propylene. The process typically involves the following steps:

- Preparation of feedstock: The first step in the production of polypropylene is the preparation of the feedstock, which consists of propylene and a catalyst. The feedstock is typically prepared in a reactor by mixing the propylene with the catalyst and any other necessary additives.

- Polymerization: The feedstock is then subjected to high temperatures and pressures in a reactor to initiate the polymerization process. During polymerization, the propylene monomers are linked together to form long chains of polypropylene.

- Purification: The resulting polymer is then purified to remove any impurities or by-products that may have formed during the polymerization process. This is typically done through a series of filtration and washing steps.

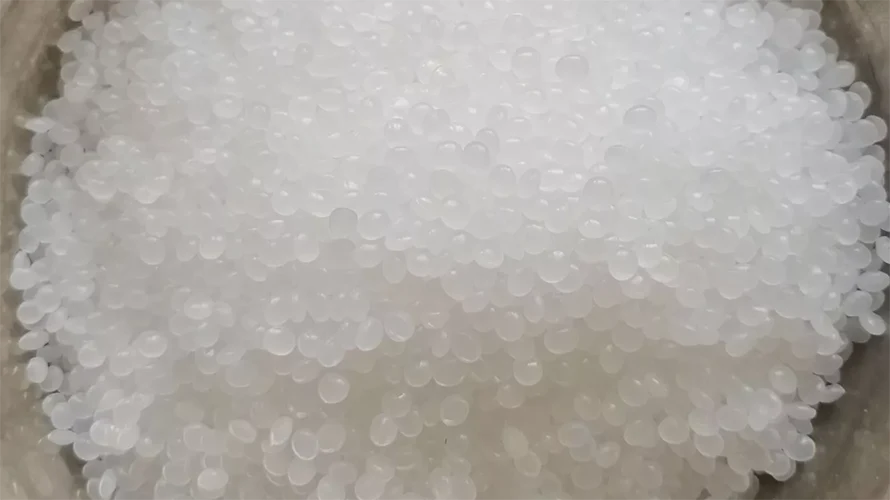

- Pelletization: The purified polymer is then melted and extruded through a die to form small, uniform pellets, which are then cooled and solidified. These pellets are then used as the raw material for the production of various polypropylene products.

There are several different methods that can be used to produce polypropylene, including bulk polymerization, solution polymerization, and gas-phase polymerization. The specific method used will depend on the desired properties of the final product and the desired production rate.

Does PP Plastic Have Disadvantages?

Although PP plastic has a wide range of advantages, it still has some disadvantages include:

- Brittle in low temperature: PP becomes brittle at low temperatures, so it may crack or break in cold environments.

- UV sensitivity: PP can be affected by UV light, which can cause it to degrade over time.

- Lack of transparency: PP is not as transparent as other plastics like PET, which can limit its use in certain applications where clarity is needed.

- Stiffness: PP has a high stiffness, which makes it difficult to shape into complex shapes.

- Low scratch resistance: PP can get scratched easily and its surface can be marked if not protected or finished.

- Not suitable for high temperature: PP is not suitable for high temperature applications, over a certain temperature it lose its strength and shape.

It is important to note that these are general observations and specific properties of different types of PP may vary depending on their manufacturing methods, ingredients and additives.

Is PP Plastic Recyclable?

Polypropylene has the number “5” as its resin identification code.

PP is a thermoplastic, which means it can be melted and reshaped multiple times without losing its properties. This makes it suitable for recycling, and PP plastic is often collected, sorted, cleaned and processed in to new products. It can also be repurposed into different forms, including pellets or flakes, which can then be used to create new products.

However, recycling of PP is not as common as other materials like PET or HDPE due to lack of consumer awareness, the lack of dedicated collection programs, and the lack of market for the recycled material.

In addition, it is important to note that the recyclability of PP depends on a number of factors, such as the type of PP and the presence of any other materials or additives that may be mixed with it, making them hard to recycle.

Therefore, it’s important to check the recycling symbol and recycle the right way, by sorting out different plastic materials and checking with your local recycling facility on what they can accept.

The Properties of Polypropylene

| Item | Result |

|---|---|

| IUPAC Name | Poly(1-methylethylene) P |

| CAS Number | 9003-07-0 |

| ECHA InfoCard | 100.117.813 |

| UNII | 1ASA949VIC |

| CompTox Dashboard (EPA) | DTXSID00872805 |

| Chemical Formula | (C3H6)n |

| Density | 0.895 – 0.92 g/cm3 |

| Melting Point | 130 to 171 °C (266 to 340 °F; 403 to 444 K) |

| Typical Injection Mold Temperature | 32 – 66 °C (90 – 150 °F) |

| Heat Deflection Temperature (HDT) | 100 °C (212 °F) at 0.46 MPa (66 PSI) |

| Tensile Strength | 32 MPa (4700 PSI) |

| Flexural Strength | 41 MPa (6000 PSI) |

| Specific Gravity | 0.91 |

| Shrink Rate | 1.5 – 2.0 % (.015 – .02 in/in) |

Content Manager at UKPACK. I have extensive experience in the packaging industry and specialize in creating engaging content. I’m passionate about staying ahead of industry trends.

Can I Put Toothpaste in a Pump Bottle? [Pros & Cons Explained]

A few years ago, I noticed something frustrating about traditional toothpaste tubes—they always left behind wasted product no matter how much I tried to squeeze them. The cap would [...]

Aerosols vs. Spray Systems: A Comprehensive Guide to Choosing the Right Option

When it comes to packaging design, especially in the beauty and personal care industries, the choice between aerosols and spray systems can be pretty overwhelming. Both formats serve unique [...]

Can You Bring Cologne on a Plane?

Traveling is one of life’s greatest pleasures, but it comes with its own set of challenges—especially when it comes to packing. One of the biggest dilemmas many travelers face [...]