Plastic Recycling Numbers & Codes Explained

Founder of UKPACK, Chief Packaging Designer with 18 years of experience, Red Dot Award Winner

Specialize in custom, innovative, and sustainable packaging solutions for cosmetics, skincare, personal care, hair care, food and beverage, and more.

- די געשיכטע און ציל פון פּלאַסטיק ריסייקלינג קאָודז

- פּלאַסטיק #1: ליבלינג / פּעטע (פּאַליעטאַלין טערעפטהאַלאַטע)

- פּלאַסטיק #2: הדפּע (הויך-געדיכטקייַט פּאָליעטהילענע)

- פּלאַסטיק #3: פּווק (פּאַליוויניל קלאָרייד)

- פּלאַסטיק #4: לדפּע (נידעריק געדיכטקייַט פּאָליעטהילענע)

- פּלאַסטיק #5: פּפּ (פּאַליפּראָופּאַלין)

- פּלאַסטיק #6: פּס (פּאַליסטירענע)

- פּלאַסטיק #7: אנדערע (פאַרשיידענע)

- די טשאַלאַנדזשיז פון פּלאַסטיק ריסייקלינג

- UKPACK ס ראָלע אין פּראַמאָוטינג סאַסטיינאַבאַל פּאַקקאַגינג

- צוקונפֿט טרענדס אין פּלאַסטיק ריסייקלינג און סאַסטיינאַבאַל פּאַקקאַגינג

- ווי שיינקייט בראַנדז קענען פירן דעם וועג אין סאַסטיינאַביליטי

- פארוואס פּאַרטנערס מיט UKPACK פֿאַר סאַסטיינאַבאַל פּאַקקאַגינג

- סאָף

- FAQs

- פֿאַרבונדענע רעסורסן:

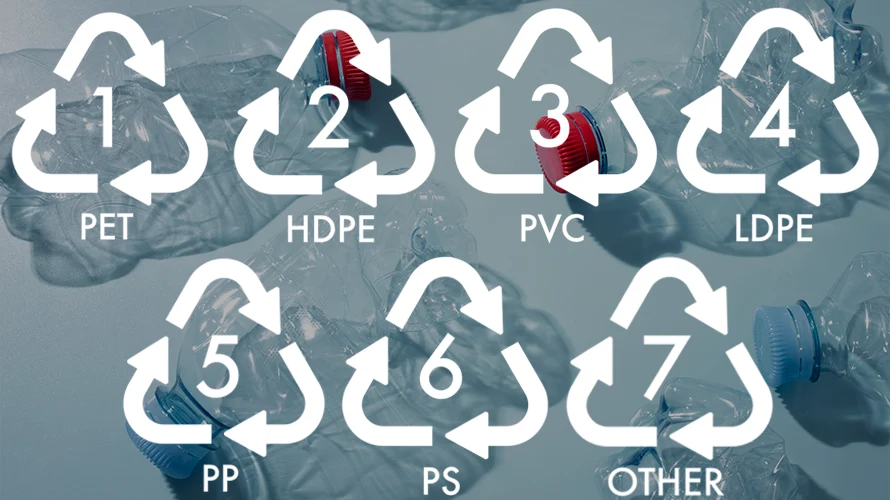

Plastic. It’s everywhere—from the bottle of water you grabbed on your way to work to the packaging that protects your favorite beauty products. But do you really know what happens to that plastic once you’re done with it? Chances are, you’ve noticed those tiny triangles with numbers inside on plastic containers. You might have assumed they mean the item is recyclable, right? Well, not so fast. Those numbers actually indicate the type of plastic resin used in the product, and not all of them are as easily recyclable as you might think.

For brands like yours that are committed to sustainability, understanding these recycling codes is essential. This guide will break down everything you need to know about plastic recycling numbers, helping you make smarter, greener choices for your packaging. At UKPACK, we’ve been working hard to offer innovative, sustainable packaging solutions, and we’re excited to share some insights with you.

The History and Purpose of Plastic Recycling Codes

First off, let’s tackle a common misconception. Those recycling codes? They weren’t created to help consumers recycle. Surprising, isn’t it? The recycling code system was introduced in 1988 by the Society of the Plastics Industry. Its main goal was to assist manufacturers in determining the type of plastic resin in their products, rather than providing consumers with information about recyclability.

You’ve probably come across those triangles and assumed that they meant “toss this in the blue bin,” but in reality, those symbols don’t always mean the item is recyclable. They’re more about the chemical makeup of the plastic. That’s why understanding these codes is key, especially if you’re in the beauty industry and trying to make your packaging more sustainable. Simply put, knowing the plastic type is the first step toward making an eco-friendly choice, but it’s not the whole story.

Plastic #1: PET/PETE (Polyethylene Terephthalate)

PET is a clear, hard plastic commonly used for single-use food and drink containers such as water and soda bottles, vegetable oil containers, peanut butter jars, and cleaning product bottles. It’s lightweight, durable, and cost-effective, making it one of the most widely used plastics globally.

Recyclability

Recycled PET, often called RPET, is the most widely recycled plastic worldwide. It’s accepted by almost all recycling programs, making it a top choice for brands focused on sustainability.

Recycled Product Uses

- Fiber for carpets and textiles

- Fleece jackets and comforter fill

- Tote bags

- RPET plastic cups

- Containers for food and beverages (bottles)

- Non-food containers

- Film and sheeting

- Strapping

Plastic #2: HDPE (High-Density Polyethylene)

HDPE is a sturdy, opaque plastic used in everyday items like milk jugs, detergent bottles, shampoo containers, and household cleaning product bottles. It’s recognized for its durability and chemical resistance, which makes it a reliable option for a wide range of products.

Recyclability

HDPE is easily recyclable and is broadly accepted at most recycling facilities. It’s often considered one of the safest plastics, as it doesn’t leach harmful chemicals into its contents, making it ideal for products with direct consumer contact.

Recycled Product Uses

- New bottles for non-food products (e.g., detergents)

- Plastic lumber and decking

- Recycling bins

- Floor tiles

- Buckets and crates

- Garden edging

Plastic #3: PVC (Polyvinyl Chloride)

PVC is a versatile plastic used in products like pipes, vinyl siding, and some packaging. It’s durable but also contains toxic chemicals like phthalates and dioxins, which can leach out over time, making it a controversial material for consumer products.

Recyclability

PVC is challenging to recycle because it contains harmful additives. While some facilities accept it for recycling, the process is complex, and contamination can be an issue. As a result, PVC often ends up in landfills or incinerators.

Recycled Product Uses

- Piping

- Decking and fencing

- Garden hoses

- Carpet backing

- Traffic cones

- Electrical cables

Plastic #4: LDPE (Low-Density Polyethylene)

LDPE is a soft, lightweight plastic commonly used in items such as grocery bags, bread packaging. It’s less rigid than other plastics, which makes it suitable for wrapping and packaging materials.

Recyclability

While LDPE is recyclable, it’s not as commonly accepted by recycling centers as PET or HDPE. However, some programs do recycle it into useful products, so it’s worth checking with your local facility.

Recycled Product Uses

- Garbage can liners

- Floor tiles

- Furniture

- Film and sheeting

- Compost bins

- Outdoor lumber

Plastic #5: PP (Polypropylene)

Polypropylene is a tough, heat-resistant plastic often found in yogurt containers, bottle caps, and medicine bottles. It’s valued for its durability and is considered safe for repeated use, making it a popular choice in various applications.

Recyclability

PP has a lower recycling rate compared to PET and HDPE, but it can still be recycled into a variety of products. Unfortunately, not all recycling programs accept PP, which limits its recyclability.

Recycled Product Uses

- Car parts (e.g., battery cases, signal lights)

- Brooms and brushes

- Ice scrapers and garden tools

- Storage bins

- Pallets and trays

Plastic #6: PS (Polystyrene)

Polystyrene, commonly known as Styrofoam, is used for disposable coffee cups, takeout containers, and packing materials. It’s lightweight and cheap but notorious for being hard to recycle and harmful to the environment.

Recyclability

PS is difficult to recycle because of its low density and the high expense involved in collecting it. It’s often excluded from municipal recycling programs, and even when recycled, it’s usually downcycled into products with limited uses.

Recycled Product Uses

- Insulation

- Protective packaging

- Light switch plates

- Desk trays

- License plate frames

- Rulers

Plastic #7: Other (Miscellaneous)

Plastic #7 is a catch-all category for plastics that don’t fit into the other six categories, including polycarbonate and plastics containing BPA. These plastics are often used in durable goods like electronic components and some food containers.

Recyclability

This category is the most challenging to recycle due to its varied composition. A lot of these plastics aren’t accepted by recycling programs and frequently end up in landfills.

Recycled Product Uses

- Custom-made products

- Plastic lumber

- Specialized items like certain industrial containers

The Challenges of Plastic Recycling

Okay, so now that you know what the numbers mean, let’s talk about the real-world challenges of plastic recycling. It’s not as simple as tossing something into the recycling bin and calling it a day. In fact, recycling plastic is a complex process, and not all plastics are created equal when it comes to recyclability.

The first hurdle? Not every recycling facility accepts all types of plastic. Most programs take PET and HDPE, but plastics #3 through #7 often get left out. That means a lot of plastic ends up in landfills, even if it technically could be recycled.

Another challenge is contamination. If different types of plastics are mixed together, it can ruin the recycling process. For example, if a batch of HDPE is mixed with PVC, the entire batch could be rendered unusable. That’s why it’s so important to ensure that your packaging materials are easy to sort and process.

At UKPACK, we believe that the best way to tackle these challenges is to design packaging that’s not only recyclable but also easy to recycle. This means using fewer materials, avoiding toxic additives, and creating packaging that can be easily disassembled.

UKPACK’s Role in Promoting Sustainable Packaging

Here at UKPACK, sustainability isn’t just a trend—it’s the foundation of everything we do. We’ve spent years innovating in the realm of sustainable packaging, and our goal is to help beauty brands like yours reduce their environmental impact without sacrificing quality or aesthetics.

One of the ways we do this is by offering packaging solutions that are made from recyclable materials like PET and HDPE. But we don’t stop there. We also focus on designing packaging that’s easy to recycle. For example, we work to create packaging that can be easily separated into its individual components, so it’s simpler for recycling facilities to process.

We’re also committed to using renewable materials and reducing waste during production. Whether it’s through minimizing the use of virgin plastic or finding ways to incorporate recycled content into our products, we’re always looking for ways to make packaging more sustainable.

Future Trends in Plastic Recycling and Sustainable Packaging

The world of plastic recycling is constantly evolving, and there are some exciting trends on the horizon that could make a big difference in how we manage plastic waste. One of the most promising developments is chemical recycling. Unlike traditional mechanical recycling, which can degrade the quality of plastic over time, chemical recycling breaks plastics down into their basic building blocks, allowing them to be remade into new materials without losing quality. This could be a game-changer for hard-to-recycle plastics like PS and #7 plastics.

Another trend to watch is the rise of bioplastics. Made from renewable resources like corn starch or sugarcane, bioplastics offer an alternative to traditional petroleum-based plastics. While they’re not a perfect solution—they still require energy to produce and can be difficult to recycle—they represent a step in the right direction toward reducing our reliance on fossil fuels.

At UKPACK, we’re committed to staying at the forefront of these innovations. We’re constantly exploring new materials and technologies that can help beauty brands reduce their environmental impact. Whether it’s through using more recycled content, developing biodegradable packaging and optimizing designs for recyclability, our goal is to help brands navigate the evolving landscape of sustainable packaging. By staying ahead of these trends, we’re not just adapting to the future—we’re helping shape it.

How Beauty Brands Can Lead the Way in Sustainability

As consumers become more environmentally conscious, beauty brands have a unique opportunity to lead the charge in sustainability. Packaging is a huge part of the beauty industry, and making eco-friendly changes can have a significant impact. Here are a few strategies beauty brands can implement to reduce their environmental footprint:

Prioritize Recyclable Materials

Opting for materials like PET and HDPE that are widely recyclable is a smart move. By choosing these plastics for your packaging, you make it easier for consumers to recycle and reduce waste. Consider clearly labeling your packaging with recycling information to encourage responsible disposal.

Reduce Packaging Waste

Excessive packaging is a common problem in the beauty industry. By minimizing the amount of packaging you use—such as eliminating unnecessary layers or switching to smaller containers—you can cut down on waste and make your products more eco-friendly.

Explore Refill Options

Refillable packaging is an exciting trend gaining traction in the beauty world. By offering products in refillable containers, you encourage customers to reuse packaging instead of discarding it after a single use. This not only reduces plastic waste but also strengthens brand loyalty by encouraging repeat purchases.

Use Recycled Content

By integrating recycled materials into your packaging, your brand can greatly decrease its carbon footprint and contribute more positively to environmental sustainability. Recycled plastic, paper, and glass are all excellent options for sustainable packaging. Plus, using recycled content demonstrates your brand’s commitment to sustainability, which resonates with eco-conscious consumers.

Educate Consumers

Sustainability efforts don’t stop at your packaging choices. Educating consumers on how to recycle or repurpose your packaging is crucial. Whether it’s through instructional videos, social media campaigns, or detailed information on your product labels, guiding your customers on sustainable practices helps extend your brand’s positive environmental impact.

Why Partner with UKPACK for Sustainable Packaging

At UKPACK, we’re not just offering packaging solutions—we’re offering sustainable futures. Our experience working with beauty brands worldwide has shown us that the demand for eco-friendly packaging is only growing, and we’re committed to meeting that demand with innovative, effective solutions.

When you partner with UKPACK, you’re not just getting packaging; you’re getting a tailored solution that aligns with your brand’s sustainability goals. Whether you’re looking to reduce your carbon footprint, switch to biodegradable materials, or optimize your packaging for recyclability, we have the expertise and resources to make it happen.

Our sustainable packaging strategy is built around three key concepts: minimizing waste, encouraging reuse, and promoting recycling. We help brands reduce their use of virgin plastics by incorporating more recycled materials, encourage the design of reusable packaging systems, and ensure that all packaging is easily recyclable. By integrating these principles into every project, we help our clients lead the way in sustainability.

Conclusion

Understanding plastic recycling numbers is just the beginning. As a brand committed to sustainability, the choices you make regarding packaging can have a significant impact on the environment. From selecting the right materials to exploring new recycling technologies, every decision matters.

At UKPACK, we’re dedicated to guiding and assisting you throughout the entire process. Together, we can create packaging solutions that not only meet your needs but also contribute to a more sustainable future for all. Keep in mind that sustainability is not just an end destination; it’s an ongoing journey of improvement and commitment. And with the right choices, your brand can make a lasting difference.

FAQs

Q1. What do the numbers inside the recycling symbols mean?

The numbers inside the recycling symbols, ranging from 1 to 7, represent different types of plastic resins used in packaging. Each number identifies a specific plastic type, which affects its recyclability.

Q2. Which plastics are the most eco-friendly for packaging?

Plastics like PET (#1) and HDPE (#2) are considered the most eco-friendly because they are widely accepted in recycling programs and can be repurposed into new products.

Q3. Can bioplastics replace traditional plastics in packaging?

Bioplastics are a promising alternative to traditional petroleum-based plastics, but they come with their own challenges, such as production energy costs and recyclability issues. However, they represent a step forward in reducing reliance on fossil fuels.

Q4. How can my beauty brand reduce packaging waste?

You can reduce packaging waste by using fewer materials, offering refillable packaging options, and incorporating recycled content into your designs. These steps not only help the environment but also appeal to eco-conscious consumers.

Q5. Why is chemical recycling important for the future of plastic waste management?

Chemical recycling breaks down plastics into their basic chemical components, allowing them to be remade into new materials without degrading their quality. This technology is crucial for recycling hard-to-process plastics like polystyrene and miscellaneous #7 plastics, offering a more sustainable solution to plastic waste.

Related Resources:

Plastics – Source: almanac.com

Recycling Polyethylene Terephthalate – Source: liveabout.com

The Negative List Materials to Be Remove – Source: nestle.com

Recycling codes – Source: wikipedia.org