A quick overview of the topics covered in this article.

- What Is Plastic Injection Molding

- Plastic Injection Molding Machine

- Different Types of Injection Molding Machines

- Common Plastic Materials for Injection Molding

- The Plastic Injection Molding Process

- Advantages of Plastic Injection Molding

- Limitations of Plastic Injection Molding

- Applications of Plastic Injection Molding

- Quality Control and Inspection in Plastic Injection Molding

- Environmental Impact and Sustainability in Plastic Injection Molding

- Tips on How to Choose Good Plastic Injection Molding Service

- Conclusion

Subscribe to the UKPACK newsletter to receive regular updates on the company, products, services, upcoming exhibitions and more.

Are you in search of injection molded plastic parts that meet precise specifications while keeping costs in check?

If that’s the case, then this comprehensive guide is tailored just for you.

It encompasses all the essential information you require regarding plastic injection molding.

What Is Plastic Injection Molding

Plastic injection molding is a highly versatile and efficient manufacturing technique that has revolutionized the production of plastic components. The process entails injecting liquefied plastic substance into a cavity of a mold, enabling it to cool and harden, and subsequently opening the mold to obtain the end product. This process enables the mass production of complex and precise plastic components with high levels of accuracy and repeatability.

The versatility of plastic injection molding makes it widely used in various industries, including automotive, consumer electronics, medical devices, packaging, appliances, aerospace, and toys. With its ability to produce intricate shapes and designs, plastic injection molding has become an essential part of modern manufacturing.

Plastic Injection Molding Machine

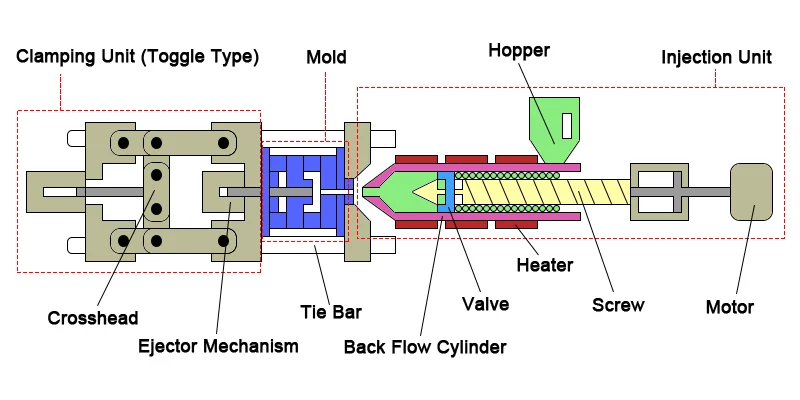

The injection molding machine is divided into two units: the clamping unit and the injection unit.

The clamping unit has several functions, including opening and closing the mold, as well as ejecting the finished products. There are two types of clamping methods: the toggle type, illustrated in the figure below, and the straight-hydraulic type, where a mold is directly opened and closed using a hydraulic cylinder.

The injection unit, on the other hand, is responsible for melting the plastic through heat and injecting the molten plastic into the mold.

By rotating the screw, the plastic material from the hopper is melted and gathered in front of it, a process known as metering. When the necessary quantity of molten plastic has been collected, the injection process initiates.

While the molten plastic flows into the mold, the machine controls the speed at which the screw moves, known as the injection speed. Additionally, it regulates the dwell pressure once the cavities are filled with molten plastic.

The shift from controlling speed to controlling pressure happens when either the position of the screw or the injection pressure reaches a predetermined value.

Different Types of Injection Molding Machines

Injection molding machines are available in various types, each offering unique features and benefits. These machines play a crucial role in the plastic injection molding process by melting and injecting plastic into molds to create a wide range of products. Let’s explore the different types of injection molding machines:

1. Hydraulic Injection Molding Machines

Overview: Hydraulic injection molding machines are the most widely used and traditional type of machines in the industry. They operate using hydraulic systems to generate the necessary force for the injection process.

Features and Advantages: Hydraulic machines offer excellent control over the molding process, allowing precise control of the injection speed, pressure, and temperature. They are known for their high production rates and the ability to handle a wide range of materials. Hydraulic machines are particularly suitable for large-scale production and applications that require high clamping forces.

Limitations: Hydraulic machines consume more energy compared to other types and may have longer cycle times due to slower injection speeds. They also require more maintenance and produce more noise and vibrations.

2. Electric Injection Molding Machines

Overview: Electric injection molding machines are becoming increasingly popular due to their energy efficiency and precision. These machines utilize electric servo motors to drive the various functions of the injection process.

Features and Advantages: Electric machines offer enhanced energy efficiency by utilizing power only when required, resulting in lower energy consumption compared to hydraulic machines. They provide high precision and repeatability, allowing for tight tolerances and accurate control of the injection parameters. Electric machines also produce less noise, have faster cycle times, and offer improved cleanliness.

Limitations: Electric machines are generally more expensive upfront compared to hydraulic machines. They may have limitations in terms of clamping force and the size of the molds they can accommodate. Additionally, they may require additional cooling systems due to the heat generated by the electric motors.

3. Hybrid Injection Molding Machines

Overview: Hybrid injection molding machines combine the benefits of hydraulic and electric machines, offering a balance between energy efficiency and performance. These machines utilize both hydraulic power and electric servo motors to drive the injection process.

Features and Advantages: Hybrid machines provide improved energy efficiency compared to hydraulic machines while maintaining high performance and precision. They offer flexibility in adjusting the energy consumption based on the specific requirements of the injection process. Hybrid machines also provide excellent control over the injection speed, pressure, and temperature, ensuring accurate and consistent molding results.

Limitations: Hybrid machines may still consume more energy compared to fully electric machines. They also require regular maintenance and may have a higher initial investment cost.

Common Plastic Materials for Injection Molding

Plastic injection molding supports a wide range of materials, each with its own unique properties and characteristics. The choice of material depends on the specific requirements of the application, such as mechanical strength, heat resistance, chemical resistance, and appearance. Here are some of the common plastic materials used in injection molding:

1. Polyethylene (PE)

Polyethylene is a versatile thermoplastic material known for its excellent chemical resistance and low cost. It is available in different variations, including high-density polyethylene (HDPE) and low-density polyethylene (LDPE). HDPE offers high stiffness and strength, making it suitable for applications requiring structural integrity, while LDPE is more flexible and has better impact resistance.

Properties: Polyethylene is a versatile thermoplastic material known for its excellent chemical resistance, low moisture absorption, and good electrical insulation properties. It has a low coefficient of friction and is resistant to impact, making it suitable for various applications.

Applications: PE is commonly used in packaging, automotive components, toys, and pipes. High-density polyethylene (HDPE) is used for containers, while low-density polyethylene (LDPE) is preferred for flexible applications like films and bags.

Grades and Brands: Some popular grades of PE include HDPE (High-Density Polyethylene), LDPE (Low-Density Polyethylene), and LLDPE (Linear Low-Density Polyethylene). Well-known brands in the market include Dow Chemical’s Dowlex, ExxonMobil’s Exceed, and LyondellBasell’s Lupolen.

2. Polypropylene (PP)

Polypropylene is a popular choice for injection molding due to its excellent chemical resistance, low density, and good impact strength. It is commonly used in the production of containers, automotive components, and consumer products. Polypropylene can be easily molded and exhibits good dimensional stability.

Properties: Polypropylene is a lightweight thermoplastic with excellent chemical resistance, low moisture absorption, and good fatigue resistance. It offers high tensile strength, stiffness, and impact resistance, making it suitable for demanding applications.

Applications: PP is commonly used in automotive parts, cosmetic packaging, consumer products, and medical devices. It is widely used for caps and closures, containers, and household goods.

Grades and Brands: Popular PP grades include homopolymer PP and copolymer PP. Well-known brands in the market include Basell’s Moplen, Braskem’s Pro-fax, and ExxonMobil’s PP.

3. Acrylonitrile Butadiene Styrene (ABS)

ABS is a widely used engineering thermoplastic known for its excellent impact resistance, dimensional stability, and toughness. It is a versatile material that can be easily modified to enhance specific properties. ABS is commonly used in the automotive industry for interior and exterior components, as well as in consumer electronics, appliances, and toys.

Properties: ABS is a tough and rigid thermoplastic with good impact resistance, dimensional stability, and heat resistance. It offers excellent surface finish and can be easily processed and painted.

Applications: ABS is widely used in automotive components, consumer electronics, appliances, and toys. It is commonly used for interior and exterior parts, such as dashboards, trim panels, and housings.

Grades and Brands: ABS is available in various grades with different impact strengths, flow properties, and heat resistance. Some popular brands include LG Chem’s Lustran, Chi Mei Corporation’s Chimei, and Styrolution’s Luran.

4. Polycarbonate (PC)

Polycarbonate is a transparent and highly impact-resistant material commonly used in applications that require clarity and strength. It offers excellent heat resistance, making it suitable for applications exposed to high temperatures. Polycarbonate is commonly used in automotive lighting, electronic components, and safety equipment.

Properties: Polycarbonate is a transparent and impact-resistant thermoplastic with high heat resistance and excellent dimensional stability. It offers good electrical insulation properties and is lightweight.

Applications: PC is commonly used in automotive lighting, electrical enclosures, safety equipment, and consumer goods. It is also widely used for applications that require optical clarity, such as lenses and protective covers.

Grades and Brands: PC is available in different grades, including general-purpose grades and flame-retardant grades. Well-known brands include Covestro’s Makrolon, Sabic’s Lexan, and Teijin’s Panlite.

5. Polyethylene Terephthalate (PET)

PET is a popular choice for packaging applications due to its clarity, toughness, and excellent barrier properties. It is commonly used for bottles, containers, and food packaging. PET is known for its recyclability, making it a preferred choice for sustainable packaging solutions.

Properties: PET is a transparent thermoplastic with excellent mechanical properties, chemical resistance, and barrier properties. It has good dimensional stability, low moisture absorption, and is easily recyclable.

Applications: PET is commonly used for beverage bottles, food containers, packaging films, and textile fibers. It is widely used in the packaging industry due to its clarity and strength.

Grades and Brands: PET is available in different grades, including amorphous PET and crystalline PET. Well-known brands include Indorama Ventures’ Polyclear, Far Eastern New Century’s FarEasTone, and Jiangsu Sanfangxiang’s Xiangxue.

6. Polyoxymethylene (POM)

Polyoxymethylene, also known as acetal or Delrin, is a high-strength engineering plastic with good dimensional stability and low friction properties. It is commonly used in applications requiring precise and low-friction components, such as gears, bearings, and electrical connectors.

Properties: Polyoxymethylene, also known as acetal or Delrin, is a high-strength engineering plastic with good dimensional stability, low friction, and excellent wear resistance. It exhibits low moisture absorption and demonstrates resistance to various chemicals.

Applications: POM is commonly used in precision mechanical parts, gears, bearings, and electrical connectors. It is suitable for applications that require low friction and high stiffness.

Grades and Brands: POM is available in different grades, including copolymer POM and homopolymer POM. Some popular brands include DuPont’s Delrin, BASF’s Ultraform, and Ticona’s Celcon.

7. Nylon (PA)

Nylon is a strong and durable engineering thermoplastic known for its excellent mechanical properties and resistance to wear and abrasion. It is commonly used in applications that require high strength, such as automotive parts, industrial components, and consumer goods.

Properties: Nylon is a strong and durable engineering thermoplastic with excellent mechanical properties, including high tensile strength and good impact resistance. It offers high wear resistance and low friction properties.

Applications: Nylon is commonly used in automotive parts, industrial components, consumer goods, and electrical connectors. It is suitable for applications that require high strength and toughness.

Grades and Brands: Nylon is available in various grades, including nylon 6, nylon 6/6, and nylon 6/12. Some well-known brands include DuPont’s Zytel, BASF’s Ultramid, and DSM’s Stanyl.

8. Polystyrene (PS)

Polystyrene is a versatile material known for its clarity, low cost, and ease of processing. It is commonly used in packaging, disposable products, and consumer goods. Polystyrene can be rigid or foamed, depending on the desired properties.

Properties: Polystyrene is a versatile thermoplastic with excellent clarity, low cost, and good dimensional stability. It is lightweight, rigid, and offers good electrical insulation properties.

Applications: PS is commonly used in packaging, disposable products, consumer goods, and insulation materials. It is widely used for food containers, disposable cutlery, and protective packaging.

Grades and Brands: PS is available in various grades, including general-purpose grades and high-impact grades. Some popular brands include Total’s Styrolution, Ravago’s Styron, and SABIC’s Luran.

9. Acrylic (PMMA)

Acrylic is a versatile material known for its optical clarity and impact resistance. It offers a wide range of design possibilities and is often chosen for applications that require transparency and durability. With its excellent weatherability and UV resistance, acrylic is a preferred choice for outdoor signage and architectural applications. The ease of fabrication and shaping makes it popular among designers and manufacturers.

Properties: Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic with excellent optical clarity, high impact resistance, and weatherability. It offers good UV resistance and is less prone to yellowing compared to other transparent plastics. Acrylic has a high surface hardness and can be easily fabricated, shaped, and polished.

Applications: Acrylic is commonly used in various applications that require transparency and impact resistance, such as automotive lighting, signage, display cases, and architectural glazing. It is also used in medical devices, optical lenses, and furniture.

Grades and Brands: Acrylic is available in different grades, including general-purpose grades and impact-modified grades. Some popular brands include Lucite International’s Lucite, Mitsubishi Chemical’s Diakon, and Evonik’s Plexiglas.

The Plastic Injection Molding Process

At first glance, the injection molding process may appear straightforward, but it actually requires tight control over various parameters to ensure the production of high-quality plastic components. Gaining a thorough understanding of the process and its parameters will assist you in identifying plastic component manufacturers who can deliver the quality and consistency you require.

Step 1: Selecting the Right Thermoplastic and Mold

Selecting the right thermoplastics and molds is crucial before commencing the injection molding process, as these elements play a vital role in shaping and forming the final components. Manufacturers must carefully consider how the thermoplastic material and mold interact, as certain plastics may not be suitable for specific mold designs.

A mold tool consists of two parts: the cavity and the core. The cavity remains stationary and serves as the space where the plastic is injected, while the core is a movable component that fits into the cavity, aiding in the formation of the final shape of the component. Depending on requirements, mold tools can be designed to produce multiple or intricate components. These tools are typically made from steel or aluminum, as they need to withstand the repeated high pressures and temperatures involved in the process.

Developing mold tools is a time-consuming and costly endeavor due to the intricate design and high-quality materials involved. Therefore, it is advisable to create and test prototype tools using computer-aided design (CAD) and 3D printing technology before producing the final customized mold. These tools allow for digital development or the creation of a prototype mold, which can then be tested with the chosen thermoplastic material in the injection molding machine.

Thoroughly testing the mold tool with the appropriate thermoplastic is essential to ensure that the final component possesses the desired properties. Each thermoplastic offers distinct characteristics and varying resistance to temperature and pressure, determined by their molecular structure. Plastics with an organized molecular structure are referred to as semi-crystalline, while those with a less structured arrangement are known as amorphous plastics.

Different thermoplastics exhibit unique properties that make them suitable for specific molds and components. The following are the most common thermoplastics used in injection molding, along with their characteristics:

- Acrylonitrile-Butadiene-Styrene (ABS) provides components with a smooth, rigid, and durable finish, which is highly beneficial for applications that demand excellent tensile strength and stability.

- Nylons (PA): Nylons come in various types, each offering different properties. Generally, nylons possess good temperature and chemical resistance, as well as the ability to absorb moisture.

- Polycarbonate (PC): PC is a lightweight, high-performance plastic known for its exceptional impact strength, stability, and favorable electrical properties.

- Polypropylene (PP): PP is semi-rigid, translucent, and tough, with excellent fatigue and heat resistance.

The choice of thermoplastic depends on the specific characteristics required by manufacturers for their final component and the design of the mold tool. For instance, if a lightweight part with electrical properties is needed, PC may be suitable, as long as the mold operates below 135°C and at moderate pressures that the plastic can withstand.

After conducting testing and making the appropriate selection of thermoplastic material and mold, the injection molding process can be initiated.

Step 2: Feeding and Melting the Thermoplastic

Injection molding machines can be powered by either hydraulic or electric systems. Essentra Components is increasingly replacing its hydraulic machines with electric-powered ones, resulting in notable cost and energy savings. These machines consist of essential components, including a feeder or “hopper” at the top, a cylindrical heated barrel with an injection screw, a gate at the barrel’s end, and the chosen mold tool connected to the gate.

To initiate the process, raw pellets of the selected thermoplastic are introduced into the hopper. As the screw rotates, the pellets gradually move into the machine’s barrel. The screw’s rotation, along with the barrel’s heat, progressively heats and melts the thermoplastic, transforming it into a molten state.

Maintaining precise temperatures at this stage is crucial to ensure efficient injection of the plastic and accurate formation of the final part.

Step 3: Injecting the Plastic into the Mold

Upon reaching the end of the barrel, the molten plastic triggers the closure of the gate, which controls the injection process. Simultaneously, the screw retracts, drawing a specific amount of plastic and increasing the pressure within the screw for injection. Simultaneously, the two sections of the mold tool are brought together, applying substantial clamp pressure to secure them in place.

It is crucial to balance the injection pressure and clamp pressure to ensure proper formation of the part and prevent any plastic from escaping the tool during injection. When the desired pressure is attained in both the tool and screw, the gate opens, allowing the screw to advance and injecting the molten plastic into the mold.

Step 4: Cooling and Solidification

As the molten plastic is injected into the mold cavity, a critical phase of the injection molding process commences—the cooling and solidification stage. During this stage, the temperature of the molten plastic gradually decreases, allowing it to transform from a fluid state into a solid form. This transformation is essential for achieving the desired shape, structural integrity, and dimensional accuracy of the final plastic part.

To facilitate efficient cooling, the mold incorporates a network of strategically placed cooling channels. These channels serve the vital purpose of extracting heat from the molten plastic, accelerating the cooling process and promoting uniform solidification. The design and placement of these cooling channels are carefully engineered to ensure optimal heat transfer and minimize any potential cooling-related defects.

The cooling time, which refers to the duration required for the plastic to sufficiently solidify, is meticulously controlled. This control is crucial to strike the delicate balance between allowing adequate time for the plastic to solidify completely and preventing excessive cooling that may lead to defects or deformations. The cooling time varies depending on factors such as the type of plastic material used, the complexity of the part’s geometry, and the desired quality standards.

During the cooling and solidification stage, it is imperative to maintain consistent cooling conditions throughout the mold. This helps to prevent variations in cooling rates, which could result in internal stresses, warpage, or uneven shrinkage of the plastic part.

Step 6: Ejection and Finishing

Once the plastic part has reached the appropriate level of cooling and solidification, the mold opens to initiate the ejection process. Ejection pins or mechanisms are strategically positioned within the mold to safely and efficiently remove the part without causing any damage or distortion. This step requires precision to ensure the part is released smoothly and accurately.

Following ejection, the part may undergo additional finishing processes to achieve the desired final appearance and functionality. These finishing steps address any remaining imperfections or excess material. Trimming is commonly performed to remove any flash or excess plastic that may have formed during the injection process. Smoothin rough edges and surfaces can be done using various techniques such as sanding or polishing. Additionally, specific surface textures or markings may be applied to meet specific design requirements or enhance the part’s aesthetics.

The ejection and finishing stage is crucial for ensuring the part meets the specified criteria and achieves the desired level of quality and functionality. Proper ejection techniques minimize the risk of damage to the part or the mold, while the finishing processes refine the part’s surface and overall appearance.

Step 7: Quality Control and Inspection

The last stage in the plastic injection molding process is dedicated to quality control and inspection to ensure the produced parts meet the predetermined standards. This step plays a vital role in guaranteeing the overall quality, functionality, and reliability of the final products. Rigorous testing procedures are implemented to assess various aspects of the parts, including dimensional accuracy, mechanical strength, visual appearance, and other specified criteria.

During the quality control phase, highly skilled technicians utilize advanced measuring tools and equipment to perform comprehensive inspections on the manufactured parts. This involves taking precise measurements to verify that the dimensions of the parts align with the specifications outlined in the design. Additionally, mechanical tests, such as stress or load testing, may be conducted to assess the strength and durability of the parts under real-world conditions. Visual inspections are carried out to identify any cosmetic imperfections, such as surface defects or color inconsistencies, ensuring the parts meet the desired aesthetic standards.

Should any defects or deviations from the required standards be detected, appropriate corrective measures are implemented. This may involve adjusting the parameters of the injection molding process, modifying the mold design, or fine-tuning the material selection.

Advantages of Plastic Injection Molding

Plastic injection molding provides a multitude of advantages compared to alternative manufacturing processes. Some key advantages include:

1. Cost-Effectiveness

Plastic injection molding is a cost-effective method for mass production. Once the initial tooling costs are covered, the per-unit cost significantly decreases with higher production volumes. The ability to produce large quantities of identical parts quickly and efficiently makes plastic injection molding a cost-efficient choice for many industries.

2. Design Flexibility

One of the most significant advantages of plastic injection molding is its design flexibility. The process allows for the production of complex and intricate shapes that may be challenging or impossible to achieve with other manufacturing methods. Designers have the freedom to incorporate features such as undercuts, thin walls, and complex geometries into their designs, opening up new possibilities for product innovation.

3. High Accuracy and Repeatability

Plastic injection molding offers exceptional precision and accuracy in producing plastic components. The molds used in the process are precisely machined to the desired specifications, ensuring consistent and repeatable results. This level of accuracy is crucial, especially in industries where tight tolerances and precise dimensions are required.

4. Wide Range of Materials

Plastic injection molding supports a wide range of materials, allowing manufacturers to choose the most suitable material for their specific applications. From commodity plastics like polyethylene and polypropylene to engineering-grade materials such as ABS, nylon, and polycarbonate, the versatility of plastic injection molding accommodates diverse material requirements.

5. Efficient Production Rates

Plastic injection molding machines are capable of producing a large number of parts in a relatively short amount of time. The high-speed injection process, combined with rapid cooling and ejection, enables manufacturers to achieve high production rates. This efficiency is essential for meeting tight production schedules and satisfying market demands.

6. Minimal Post-Processing

Unlike some manufacturing processes that require extensive post-processing, plastic injection molding often produces finished parts that require little to no additional work. The parts typically have smooth surfaces and require minimal trimming or finishing operations, reducing production time and costs.

Limitations of Plastic Injection Molding

While plastic injection molding offers significant advantages, it also has certain limitations that need to be considered. These limitations include:

1. High Initial Tooling Costs

The cost of creating the molds used in plastic injection molding can be relatively high, especially for complex and intricate designs. The molds require precision machining and may need additional features like slides, lifters, or inserts, which can add to the overall tooling cost. This initial investment may deter some businesses, particularly those with lower production volumes or limited budgets.

2. Longer Lead Times for Tooling Development

The design and fabrication of molds used in plastic injection molding can take several weeks to months, depending on the complexity of the part and the availability of resources. This longer lead time can impact the overall project timeline, especially when quick turnaround is required.

3. Limited Feasibility for Low-Volume Production

When it comes to production runs with high volumes, plastic injection molding proves to be the most cost-effective option. For low-volume production or prototyping purposes, the initial tooling costs may outweigh the benefits of injection molding. In such cases, alternative manufacturing methods like 3D printing or CNC machining may be more suitable.

4. Design Restrictions

Certain design considerations need to be taken into account when designing for plastic injection molding. Features such as draft angles, wall thickness, and undercuts are essential to ensure proper mold filling, ejection, and overall part quality. Designers must work closely with mold makers and injection molding experts to optimize designs for the injection molding process.

5. Material Selection Limitations

While plastic injection molding supports a wide range of materials, not all plastics are suitable for the process. Factors such as melt flow properties, shrinkage rates, and material behavior during cooling and solidification must be considered when selecting the appropriate material for injection molding. Some materials may require specialized equipment or processing conditions, adding complexity and cost to the manufacturing process.

Applications of Plastic Injection Molding

Plastic injection molding is a versatile manufacturing process that finds application in various industries and product categories. The ability to produce complex shapes, intricate details, and precise dimensions makes it suitable for a wide range of applications. Here are some notable industries and products that heavily rely on plastic injection molding:

1. Automotive Industry

Plastic injection molding plays a crucial role in the automotive industry, where it is used to manufacture components ranging from interior parts to exterior body panels. Dashboard components, door panels, bumpers, grilles, and lighting fixtures are just a few examples of automotive parts produced through injection molding. The process offers design flexibility, lightweight solutions, and cost-effectiveness, contributing to enhanced vehicle performance and fuel efficiency.

2. Consumer Electronics

The production of consumer electronic devices heavily relies on plastic injection molding. From mobile phone casings and computer keyboards to television frames and audio equipment, injection molding enables the creation of sleek, durable, and visually appealing products. The process allows for the integration of various features, such as snap-fit assemblies, precise button placement, and seamless designs, catering to the demands of the ever-evolving consumer electronics market.

3. Packaging Industry

Injection molding plays a significant role in the packaging industry, providing cost-effective solutions for manufacturing plastic containers, bottles, caps, and closures. The ability to produce consistent, high-quality packaging products at high volumes makes injection molding ideal for this industry. The process enables the creation of custom shapes, sizes, and designs, ensuring efficient storage, transportation, and protection of a wide range of consumer goods.

4. Medical and Healthcare

Plastic injection molding plays a critical role in the medical and healthcare sector, where precision, cleanliness, and compliance with strict regulations are paramount. Injection molding is used to produce a variety of medical devices, including syringes, inhalers, surgical instruments, and implantable components. The process allows for the production of sterile and biocompatible products, contributing to the advancement of medical technology and improving patient care.

5. Consumer Goods and Appliances

Plastic injection molding is widely utilized in the manufacturing of consumer goods and appliances. From kitchenware and household products to toys and sporting goods, injection molding offers a cost-effective method to produce high-quality, durable, and visually appealing items. The process enables manufacturers to meet consumer demands for ergonomic designs, vibrant colors, and functional features, enhancing the overall user experience.

Quality Control and Inspection in Plastic Injection Molding

Quality control and inspection are essential aspects of the plastic injection molding process to ensure the production of high-quality and defect-free components. Various techniques and standards are employed to maintain stringent quality standards throughout the manufacturing process. Let’s explore some key aspects of quality control and inspection in plastic injection molding:

1. Testing and Measuring Techniques

To assess the quality of plastic injection molded parts, testing and measuring techniques are employed. These techniques include dimensional measurements, functional testing, material testing, and performance evaluation. Advanced tools and equipment such as coordinate measuring machines (CMMs), optical comparators, and gauges are used to verify critical dimensions, tolerances, and part specifications. Functional testing may involve subjecting the parts to simulated operational conditions to ensure their performance and reliability.

2. Dimensional Accuracy and Tolerances

Dimensional accuracy and adherence to specified tolerances are crucial in plastic injection molding. Sophisticated metrology equipment is used to measure and verify the dimensional accuracy of the molded parts. This involves comparing the measurements with the design specifications and ensuring that the parts meet the required tolerances. Maintaining dimensional accuracy is vital for achieving proper fit and function, especially in assemblies where multiple components must work together seamlessly.

3. Non-Destructive Testing Methods

Non-destructive testing (NDT) methods are employed to identify potential defects or imperfections in the molded parts without causing any damage. These methods include visual inspection, ultrasonic testing, X-ray inspection, and dye penetrant testing. Visual inspection is performed to detect any surface defects, such as cracks, flash, or sink marks. Ultrasonic testing and X-ray inspection are used to identify internal defects like voids or air bubbles. Dye penetrant testing is useful for detecting surface cracks or discontinuities that may be invisible to the naked eye.

4. Quality Standards and Certifications

Plastic injection molding companies adhere to various quality standards and certifications to ensure consistent quality and meet customer requirements. Standards such as ISO 9001:2015 define the criteria for a quality management system and encompass various aspects of the manufacturing process, including design, development, production, and inspection. Additionally, specific industry standards, such as automotive industry standards (e.g., ISO/TS 16949), ensure compliance with the quality requirements specific to particular sectors.

Certifications from recognized bodies validate a company’s commitment to quality. These certifications may include ISO certifications, industry-specific certifications, or customer-specific certifications. Acquiring and maintaining these certifications demonstrates the company’s dedication to meeting the highest quality standards and provides confidence to customers in the reliability and consistency of the manufactured parts.

Environmental Impact and Sustainability in Plastic Injection Molding

Plastic injection molding, like any manufacturing process, has environmental implications. However, the industry has been actively addressing these concerns and working towards greater sustainability. Let’s explore some key aspects related to the environmental impact and sustainability of plastic injection molding:

1. Challenges and Solutions for Sustainability

The challenges associated with the environmental impact of plastic injection molding include the consumption of energy and resources, generation of waste, and carbon emissions. To mitigate these challenges, manufacturers are adopting various sustainable practices. This includes optimizing manufacturing processes to minimize energy consumption, implementing efficient waste management systems, and reducing greenhouse gas emissions. Additionally, companies are exploring innovative approaches to reduce the overall environmental footprint, such as using renewable energy sources and implementing closed-loop systems.

2. Recycling and Waste Management

Recycling and proper waste management play crucial roles in minimizing the environmental impact of plastic injection molding. Manufacturers are increasingly focusing on recycling plastic waste generated during the production process and post-consumer waste. This involves implementing recycling programs, segregating waste streams, and utilizing recycled materials in the manufacturing process. By embracing these practices, the industry reduces the demand for virgin plastics, conserves resources, and decreases the amount of plastic waste ending up in landfills or oceans.

3. Biodegradable and Bio-Based Plastics

Another avenue towards sustainability in plastic injection molding is the utilization of biodegradable and bio-based plastics. These materials are specifically engineered to undergo natural degradation over time, thus minimizing their environmental footprint. Biodegradable plastics can decompose through biological processes, while bio-based plastics are derived from renewable sources such as corn or sugarcane. By incorporating these materials into the manufacturing process, the industry reduces its reliance on fossil fuels, lowers carbon emissions, and offers environmentally friendly alternatives.

4. Industry Initiatives and Regulations

The plastic injection molding industry actively participates in various sustainability initiatives and adheres to regulations aimed at reducing its environmental impact. Collaborative efforts among manufacturers, industry associations, and government bodies drive the development of sustainable practices and technologies. Organizations are implementing voluntary initiatives, such as eco-labeling programs and certifications, to promote environmentally responsible practices. Additionally, regulatory measures related to waste management, recycling targets, and carbon emissions drive the industry towards more sustainable operations.

Tips on How to Choose Good Plastic Injection Molding Service

Selecting the right plastic injection molding service can greatly impact the success of your manufacturing projects. To ensure the production of high-quality plastic components, consider the following tips when choosing a service provider:

1. Experience

Look for a company with a solid track record and extensive experience in plastic injection molding. A service provider with years of industry experience is more likely to deliver excellent results.

2. Services

Assess the variety of services provided by the company and consider their scope and suitability for your specific needs. Ideally, they should offer a comprehensive suite of solutions, including design assistance, prototyping, tooling, and production. A one-stop-shop can streamline the manufacturing process and save you time and effort.

3. Design Capabilities

The company should have skilled professionals who can assist with design aspects. They should be equipped with specialized CAD software that allows you to create precise and customized parts. Whether starting from scratch or modifying existing designs, the software should enable seamless collaboration.

4. Material Expertise

Choose a service provider that has expertise in working with a wide range of plastic materials. Different plastics have unique properties, and the company should have the knowledge and experience to handle the specific material required for your project.

5. Equipment and Technology

Ensure that the company has state-of-the-art equipment and technology for plastic injection molding. Modern machinery and advanced technologies enhance the precision and efficiency of the manufacturing process. This, in turn, ensures the production of high-quality parts that meet your specifications.

6. Technical Support

A reliable service provider should offer excellent technical support to address any issues that may arise during the production process. Prompt and efficient technical assistance can minimize downtime and keep your project on track.

7. Cost Considerations

While cost is an important factor, prioritize quality over price. Be cautious of excessively low-cost options that may compromise the quality of the final products. Strike a balance between affordability and the service provider’s reputation for delivering superior results.

8. Accreditations

Verify if the company holds relevant certifications and accreditations. The standard accreditation for quality management systems is ISO 9001:2015. Additionally, certifications such as BS/EN 1090-1 demonstrate a commitment to meeting industry standards and regulations.

9. Knowledgeable Sales Staff

Opt for a plastic injection molding service with a knowledgeable sales team. A well-trained sales staff can understand your requirements, provide valuable insights, and ensure that your project is executed to the highest standard, efficiently, and within budget.

Remember, plastic injection molding is a complex process, and the success of your project relies on choosing the right service provider. Seek a company that not only comprehends your vision but also pays meticulous attention to detail. With a skilled and dedicated team, you can expect a finished product that exceeds your expectations.

Conclusion

When it comes to plastic injection molding services, precision and complexity are crucial factors. This advanced manufacturing technique enables the creation of intricate and accurate plastic parts, making it a preferred choice in the industry.

If you’re in need of top-notch plastic injection molding services, look no further. Our dedicated team is well-equipped and specially trained to handle all your molding needs. Whether you require small-scale intricate parts or large-scale production runs, we have the expertise and resources to deliver exceptional results.

Don’t hesitate to reach out to us today to discuss your specific requirements and benefit from our professional plastic injection molding services. With our commitment to quality and efficiency, we guarantee to meet your expectations and provide you with reliable and precise plastic components. Contact us now and let our experienced team exceed your molding expectations.

More Resource:

Content Manager at UKPACK. I have extensive experience in the packaging industry and specialize in creating engaging content. I’m passionate about staying ahead of industry trends.

Can I Put Toothpaste in a Pump Bottle? [Pros & Cons Explained]

A few years ago, I noticed something frustrating about traditional toothpaste tubes—they always left behind wasted product no matter how much I tried to squeeze them. The cap would [...]

Aerosols vs. Spray Systems: A Comprehensive Guide to Choosing the Right Option

When it comes to packaging design, especially in the beauty and personal care industries, the choice between aerosols and spray systems can be pretty overwhelming. Both formats serve unique [...]

Can You Bring Cologne on a Plane?

Traveling is one of life’s greatest pleasures, but it comes with its own set of challenges—especially when it comes to packing. One of the biggest dilemmas many travelers face [...]