A quick overview of the topics covered in this article.

Subscribe to the UKPACK newsletter to receive regular updates on the company, products, services, upcoming exhibitions and more.

Have you ever wondered why a bottle cap fits perfectly on one bottle but not on another? The answer lies in the design of the bottle neck finishes, thread sizes, and various dimensions. Whether you’re working with cosmetics, food and beverages, or pharmaceuticals, understanding these details is crucial for optimizing your packaging. In this guide, we will explore the essential aspects of bottle neck finishes, helping you grasp the key measurements needed to select the right closure for your container. Let’s dive in and uncover the secrets of effective packaging!

What Is a Bottle Neck

A bottle neck is the slender portion of a bottle that leads to its opening, typically smaller in diameter than the main body. This design feature creates a tapered shape, allowing for a more controlled pouring or dispensing of the contents. The narrower neck not only facilitates better handling but also enables compatibility with various closures, such as caps, pumps, and droppers. This versatility is essential for ensuring a secure seal and optimal usability, making the bottle neck a critical element in packaging design across different industries.

What Is a Bottle Neck Finish

A bottle neck finish refers to the section at the top of a bottle or container where the threads are located. These threads connect with a cap or closure, ensuring the lid stays securely in place and provides a proper seal. While the term “neck finish” is commonly used for bottles due to their narrow neck leading to the opening, “thread finish” is often used for wider-mouth containers like jars. Despite these distinctions, both terms refer to the same critical feature: the point where the closure meets and seals the container.

The Role of Threads in Bottle Neck Finishes

The design, length, and number of threads on a bottle neck play a significant role in how the container is sealed. Continuous threads, the most common type of closure, work by twisting the cap onto the bottle. This ensures a tight seal and prevents leaks, making them ideal for a wide range of products, from beverages to cosmetics.

How Neck Finish Numbers Work

Manufacturers use a standardized system to describe bottle neck finishes. These specifications usually consist of two parts:

- A two-digit number that indicates the neck’s outer diameter in millimeters.

- A three-digit number that defines the thread style or finish.

These numbers are often separated by a dash, hyphen, or forward slash (e.g., 28-410 or 28/410). Sometimes, the neck size is also represented as a single number, such as “28mm.”

For example, in a 28-410 neck finish:

- 28 refers to the “T dimension,” the diameter of the neck opening, including the threads, measured in millimeters.

- 410 represents the thread finish, which indicates a single complete thread turn around the neck.

To ensure compatibility, the closure (e.g., cap or pump) must match both the width and thread style of the bottle neck. In this example, only a 28-410 cap would properly fit a bottle with a 28-410 neck finish.

How to Measure a Neck Finish

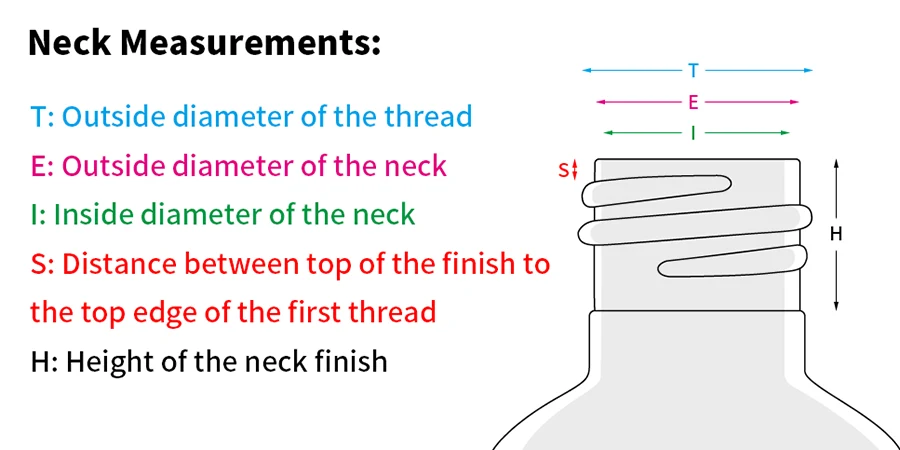

Measuring a bottle’s neck finish involves several key dimensions that ensure proper compatibility with closures and overall functionality.

T Dimension: This measures the outer diameter of the neck, including the threads. It is crucial for determining which closure will fit the bottle securely.

E Dimension: This dimension refers to the outer diameter of the neck without considering the threads. It provides insight into the mouth of the bottle and helps assess the overall design.

I Dimension: This is the inner diameter of the neck, essential for ensuring that closures, such as disc top caps with plugs, fit correctly. A well-defined I dimension is critical for effective sealing and dispensing.

S Dimension: This measures the distance from the top of the neck finish to the top edge of the first thread. It impacts how well the closure engages with the bottle, influencing the orientation and thread engagement.

H Dimension: The height of the neck finish is measured from the top of the neck down to where the outer diameter of the T dimension intersects with the shoulder of the bottle. This measurement determines the overall height and design of the neck finish.

Two essential factors for determining the compatibility between a container and its closure are:

- The neck width (known as the T Dimension, measured in millimeters)

- The style of the thread

What is Thread Style?

Thread style, also known as thread finish or thread turn, describes the design of the threads on a container’s neck, which spiral in a continuous pattern. The cap is designed with a corresponding internal spiral that aligns with the neck to create an effective seal. The Glass Packaging Institute (GPI) and the Society of Plastics Industry (SPI) have established guidelines to standardize threading for glass and plastic containers. To achieve a proper seal, it is essential for both the neck width and thread style of the container and cap to match.

Common Bottle Thread Styles

While there are many different types of thread finishes available, here are some of the most frequently used thread styles for plastic and glass containers:

Most thread styles are identified by a three-digit code, as shown previously. However, specialty caps might use additional numbers or letters to denote their neck finishes. For instance, glass containers with a lug neck finish are often labeled with codes like 2040, while unique caps, such as the Drop-Lok cap for carbonated drinks or various tamper-evident closures, may have distinct designations.

18-400 Neck Finish

The 18-400 neck finish is a widely used specification for glass bottles, particularly popular with Boston round droppers and euro-dropper bottles. These bottles are often used for storing essential oils and other oil-based products. The 18-400 neck size is specifically designed to provide a secure fit for closures such as rubber bulb droppers and phenolic caps. This ensures that the contents are sealed tightly, preventing leaks and preserving the integrity of the oils. Its application is essential for products that require precision dispensing and airtight storage, making it a favored choice in the aromatherapy and fragrance industries.

20-410 Neck Finish

The 20-410 neck finish is a prevalent choice for small plastic bottles, typically ranging in size from 1 to 4 ounces. This neck size is commonly seen in bottle designs such as Boston round, imperial-cosmo, bullet round, and cylinder round. It offers excellent versatility due to its compatibility with a wide range of caps and closures. Options include continuous thread caps for a secure seal, fine mist sprayers for even distribution, disc caps, flip-tops for easy dispensing, polytops, and yorker tips for precision application. This adaptability makes the 20-410 neck finish ideal for products like cosmetics, personal care items, and various household liquids that require both secure storage and convenient access.

24-410 Neck Finish

The 24-410 neck finish is a versatile specification widely used in packaging, primarily for plastic bottles, with a growing presence in aluminum options due to an increased focus on sustainability. This neck size accommodates bottles ranging from 2 to 16 ounces, making it suitable for a variety of applications. It is commonly found in bottle shapes like Boston round, imperial-cosmo, woozy, bullet round, and cylinder round. The 24-410 neck size is highly adaptable, compatible with a broad spectrum of closures and dispensing systems. These include continuous thread caps for a secure seal, fine mist sprayers for even application, disc top caps, flip-tops for easy access, dispensing pumps for controlled use, polytops, and yorker tips for precision dispensing. This flexibility makes it an ideal choice for products across industries, including personal care, beauty, and household cleaning, where both functionality and ease of use are essential.

28-410 Neck Finish

The 28-410 neck finish is a versatile and popular choice for medium-sized bottles, frequently used in both plastic and increasingly in aluminum due to rising demand. This neck size fits bottles ranging from 8 to 32 ounces and is often seen in shapes like Boston round, imperial-cosmo, modern round, bullet round, and cylinder round. Its versatility is highlighted by the wide array of compatible caps and closures, such as continuous thread caps, trigger sprayers, disc top caps, flip-tops, and dispensing pumps.

In particular, the 28-410 neck finish is ideal for flavored syrup bottles, as it works seamlessly with syrup pumps. These pumps are designed to provide a convenient and precise way to dispense syrups, making them indispensable in settings such as coffee shops, restaurants, and home kitchens. The combination of a 28-410 neck finish with a syrup pump ensures both secure sealing and easy, controlled dispensing, catering perfectly to the needs of those working with flavored syrups.

38-400 Neck Finish

The 38-400 neck finish is a highly adaptable type of bottle opening, commonly used across plastic, metal, and glass bottles. This neck size is one of the most versatile because it accommodates a wide range of bottle sizes, from small 4-ounce containers to large 1-gallon jugs. You’ll find this neck finish on various bottle shapes, including packers, sauce bottles, cylinder rounds, honey bears, F-style containers, cubitainers, and industrial jugs.

Due to the medium to large size of bottles with a 38-400 neck finish, the available closure options are somewhat specialized. These typically include standard continuous thread caps and child-resistant closures for safety. Additionally, there are some dispensing options like yorker spouts and flip-top lids, which are ideal for thicker liquids like honey or for solid capsules in smaller bottles, as well as for large quantities of liquid in the bigger 1-gallon bottles. This makes the 38-400 neck finish a practical choice for products ranging from viscous fluids to higher volume liquids.

38-430 Neck Finish

The 38-430 neck finish is a specialized design primarily utilized in the food and flavorings sector. This finish is typically associated with buttress bottles, which feature a distinctive shape and lip specifically engineered to facilitate smooth pouring. The unique aspect of this neck finish is its compatibility with buttress caps, which are the only type of closure that can securely seal these bottles. While the 38-430 neck finish is most commonly found on 32-ounce bottles, it is also available in smaller sizes to meet various packaging needs. This neck finish is particularly valued in applications where secure sealing and precise dispensing are crucial, ensuring product integrity and ease of use.

45-400 Neck Finish

The 45-400 neck finish is a standard in the pharmaceutical and nutraceutical industries, particularly for packer bottles. These bottles, which can be made of either plastic or glass, typically range from 175 cc to 400 cc in size. The 45-400 specification refers to both the neck diameter (45 mm) and the thread style (400), which is designed for compatibility with continuous thread closures. This design ensures a secure seal, crucial for maintaining the integrity and shelf life of products like vitamins, supplements, and medications. The straightforward threading system also makes it easy for consumers to open and close the bottles, ensuring convenience while maintaining product safety.

53-400 Neck Finish

The 53-400 neck finish is among the largest neck sizes used in bottle design, predominantly serving the pharmaceutical and nutraceutical markets. It is specifically utilized for plastic and glass packer bottles, which typically range from 400 cc to 950 cc in capacity. This neck finish features a 53 mm diameter and a 400 thread style, designed to accommodate continuous thread closures. The larger neck size is ideal for products that require easy access and efficient dispensing, such as bulk supplements or medications. The 53-400 finish ensures a secure seal while providing user-friendly access, making it a preferred choice for packaging that prioritizes both safety and convenience.

Types of Neck Finishes

Neck finishes play a crucial role in packaging, providing both functionality and aesthetic appeal. Here’s an overview of some common neck finishes, each with its unique features and applications.

Continuous Thread Neck Finish

Continuous thread neck finishes are among the most versatile and widely used in the packaging industry. These finishes allow caps to be easily screwed on and off, making them ideal for products that need to be sealed and resealed frequently. Available in sizes ranging from 15mm to 120mm, they accommodate a wide variety of liners, ensuring a secure seal.

Common Uses:

- Industries: Food and beverage, personal care, pharmaceutical, and wellness.

- Cap Types: Ratchet caps for added security, beverage caps for liquid products, phenolic caps known for their chemical resistance, spice caps for seasonings, flapper caps for controlled dispensing, and snap top caps for convenience.

Cork Neck Finish

Cork neck finishes are synonymous with tradition and elegance, often associated with premium products like wine and beer. Corks provide an airtight seal, crucial for preserving the freshness and flavor of the contents. Beyond wines, cork closures are used for spirits, olive oils, and specialty vinegars, offering a sophisticated touch while ensuring product integrity.

Common Uses:

- Industries: Wine, spirits, gourmet food products.

- Benefits: Airtight seal, traditional aesthetic, excellent for preserving taste and aroma.

Snap-On Neck Finish

Snap-on neck finishes are designed for security and ease of use. These tamper-evident caps are popular in the food and beverage industry, particularly for products like juices and milk. The BPA-free plastic ensures consumer safety, and the caps are available in various colors to enhance branding.

Common Uses:

- Industries: Dairy, juices, soft drinks.

- Benefits: Tamper-evident, colorful options for brand differentiation, easy to apply.

Crown Neck Finish

Crown neck finishes are a staple in the beverage industry, especially for beer bottles. These caps are crimped onto the bottle, providing a tight seal that reduces oxidation—a key factor in maintaining the product’s intended taste and quality. Available in a variety of colors, crown caps offer both functional and aesthetic benefits.

Common Uses:

- Industries: Beer, sodas, sparkling beverages.

- Benefits: Secure seal, color variety for branding, maintains product quality.

3 More Factors Influencing Bottle and Cap Fit

Ensuring a secure closure between bottles and caps is crucial to prevent leaks and maintain product integrity during transit. Here are three important factors to consider when choosing the right closure for your packaging needs:

Additional Packaging Components

The integration of additional components into your packaging can significantly affect how the cap fits and functions. Components like cap liners, sifter fitments, dip tubes, plug seals, and shrink bands can all influence the seal and compatibility between the cap and bottle.

- Cap Liners: These are inserted into caps to enhance sealing but may affect how the cap sits on the bottle’s neck.

- Sifter Fitments: Used often for spices and powders, these can alter the cap’s alignment.

- Dip Tubes: Common in pump bottles, the length and flexibility of the dip tube must match the bottle’s dimensions to avoid leakage.

- Plug Seals and Shrink Bands: Provide additional sealing and tamper-evidence but require precise fitting to avoid interference with cap threading.

For optimal packaging, ensure that all components work cohesively to maintain functionality and security.

Variance in Manufacturer Design

Despite industry standards, variations in design and material composition from different manufacturers can affect how well a cap fits a bottle.

- Material Differences: For example, PET plastic bottles may have different thicknesses compared to HDPE bottles, affecting the fit.

- Cap Design: Child-resistant caps often have unique threading and fit tolerances, which may differ from standard closures.

Understanding these design variances is key to ensuring compatibility. It’s advisable to work closely with your suppliers to understand these nuances and opt for compatible combinations.

Application Conditions

The success of the bottle-cap fit isn’t solely dependent on the products themselves but also on how they are applied during the packaging process.

- Fill Temperature: Hot fills can expand bottle materials, affecting cap fit during cooling.

- Pressure: High-pressure filling and capping can lead to over-tightening or under-tightening if not properly calibrated.

- Capping Process: The machinery and method used to apply caps influence the consistency and security of the closure.

To ensure a perfect fit, it’s important to test the bottle and cap under your specific production conditions. Request samples and conduct trial runs to identify any potential issues early in the process, allowing for adjustments before full-scale production.

Conclusion

Understanding bottle neck finishes and thread sizes is key to selecting the right closure for your products. With the right specifications, you can ensure a secure seal and optimal functionality for your packaging. Whether you’re working with cosmetics, food, or pharmaceuticals, choosing the correct neck finish can make all the difference. UKPACK offers a variety of closures tailored to meet your business needs, helping you achieve a perfect seal every time. Contact us now!

Content Manager at UKPACK. I have extensive experience in the packaging industry and specialize in creating engaging content. I’m passionate about staying ahead of industry trends.

The Ultimate Guide to Ergonomic Packaging Design

In today’s consumer-driven world, packaging does more than just protect a product—it shapes the entire user experience. Ergonomic packaging focuses on enhancing comfort, safety, and convenience for the consumer, [...]

How Much Is One Pump of Torani Syrup?

Torani syrups are a staple in beverage creation, adding a splash of flavor to everything from coffee to cocktails. Whether you're a home barista or a professional mixologist, one [...]

The Ultimate Guide to Bottle Neck Finishes, Thread Sizes, & Dimensions

Have you ever wondered why a bottle cap fits perfectly on one bottle but not on another? The answer lies in the design of the bottle neck finishes, thread [...]